2G Ethanol

2G Etanol production is straightforward, robust and reliable

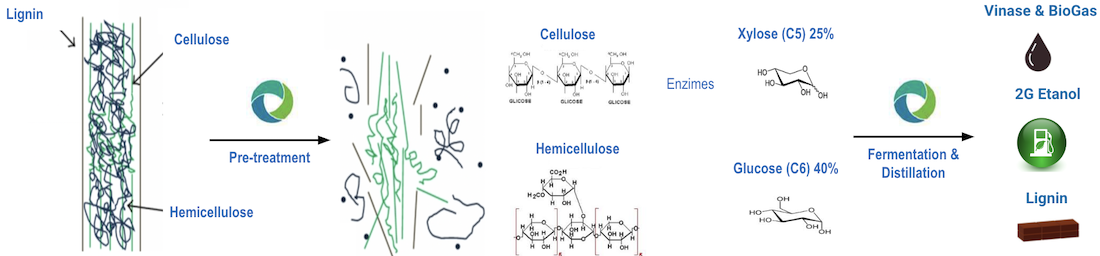

Cellulosic or 2G etanol is produced from sugar contained in plants (xylose and glucose) instead of sucrose or dextrose contained in sugar cane or corn.

Cellulosic ethanol does not compete with food, on the contrary, it uses agricultural residues such cane straw or corn stove as feedstock, increasing farms revenue.

2G ethanol has the same molecular structure, chemical properties and characteristics of conventional sugar cane or corn ethanol. The difference is that 2G ethanol is cleaner in terms of carbon emissions, with net zero potential.

GranBio has two proprietary technology platforms to produce 2G ethanol: GreenPower (GP)+ and AVAP. In both processes the biomass cellulosic wall sustained by lignin is broken in a process called pre-treatment combining pressure and temperature, or recoverable solvents, exposing the the cellulose and hemicellulose carbon chains that are cut by enzymes into 5 and 6 carbon sugars. Then those sugars are fermented by GMO yeasts and distilled to ethanol.

The potential for 2G ethanol is extraordinary. In Brazil the amount of sugar cane residues such as bagasse and straw may increase total ethanol production by more than 50% without incremental use of land. In the US corn residue, such as stover, sugar cane residue or renewable wood chips from idle pulp and paper mills offer path for SAF from ethanol to jet technologies.