AVAP

Main Cellulosic Sugar Platform for SAF and Nanocellulose

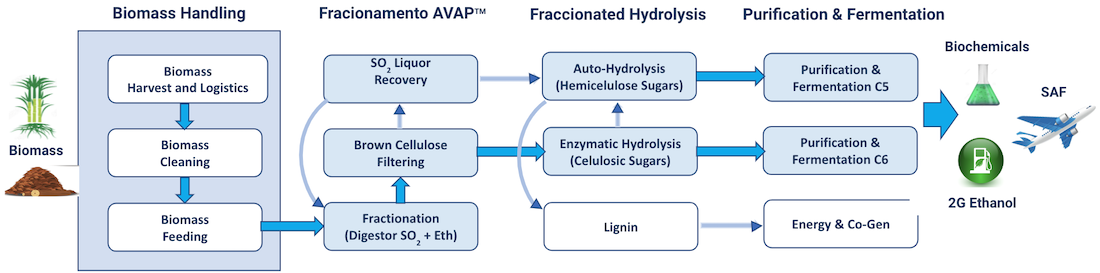

AVAP® Biomass Fractionation – Is a group of technologies capable of converting any type of biomass, including softwoods, into cellulosic sugars (e.g., glucose and xylose), lignin, cellulose pulp, and nanocellulose. A representative patent in this field is US Patent Num. 8,030,039, which discloses a process for the production of cellulosic sugars and derivatives. AVAP technology can produce pure fermentable cellulosic sugars as low as 12 cents/lb with certain biomass types, equivalent to a boe of oil of USD 65.

AVAP Process

The AVAP process is an offers several industry-leading advantages as a front-end technology with several advantages for SAF production including:

- Feedstock Agnostic: AVAP has produced clean, highly fermentable sugars from a wide variety of low-cost biomass feedstocks including hardwood and softwood forest biomass, corn stover, palm oil empty fruit bunches, sugarcane straw, wheat straw, and wood construction debris. Feedstock represents the largest cost component for 2G sugar and cellulosic ethanol production for conversion to SAF. Ability to process any low-cost biomass feedstock is a major competitive advantage for ensuring economically viable biochemicals and 2G ATJ fuels to a USD70 boe of oil.

- High Yield: AVAP provides a total sugar yield from cellulose + hemicellulose at 85–95% of theoretical with <1% sugar degradation in digestor fractionation and ~1% sugar degradation in hemicellulose hydrolysis reactor. The AVAP cellulose pulp conversion to glucose sugars is >85% glucose yield at <4 FPU enzymes per g glucan over 72 hours.

- Value-Added Co-products: AVAP glucose from cellulose performs similar to 1G corn (dextrose DE95) for conversion to biochemical co-products including n-butanol, succinic acid, bio-BDO, lactic acid, as confirmed by external conversion partners. AVAP’s patented nanocellulose co-product has been shown to reduce rolling resistance and strengthen tires, strengthen and lightweight automotive plastic composites and improve barrier properties of plastic food packaging. AVAP’s “native” colloidal lignin is not chemically modified and is odor free for use in plastic and tires and conversion to SAF with emerging lignin-to-jet technologies.

- Industry-Leading GHG Reductions: LCA modeling of AVAP ethanol from woody biomass to jet fuel shows potential NET ZERO and a 95% reduction of GHG emission compared to fossil-based jet fuel.

- Supply for Multiple SAF pathways: The AVAP “Biomass Cracker” can provide ethanol for Alcohol to jet SAF pathways and/or highly fermentable, clean sugars for both fermentation and catalytic routes to SAF.

SEE ALSO

-

SAF D.O.E. Grant is awarded to AVAPCo.